About Us

The Additive Manufacturing Laboratory is a comprehensive and centralized facility, bringing together both types of additive manufacturing - laser powder bed fusion, LENS 750, also referred to as selective laser melting, and laser-based directed energy deposition, Aconity MIDI - along with several pre- and post-process equipment for fundamental and applied research on additive manufacturing. The lab will foster UNT's interdisciplinary research in the area of advanced manufacturing.

The Fourth Industrial Revolution - the fusion of manufacturing design, process and production into one comprehensive

whole - has spurred new technology for additive manufacturing, a process that builds

3D objects through the successive layering of metals, ceramic and metal-ceramic alloys.

And, helping to pave the way to this new future of manufacturing is the University

of North Texas's new state-of-art Additive Manufacturing Laboratory located within the university's centralized Materials Research Facility, which opened

its doors to the public on Nov. 28, 2019.

The Fourth Industrial Revolution - the fusion of manufacturing design, process and production into one comprehensive

whole - has spurred new technology for additive manufacturing, a process that builds

3D objects through the successive layering of metals, ceramic and metal-ceramic alloys.

And, helping to pave the way to this new future of manufacturing is the University

of North Texas's new state-of-art Additive Manufacturing Laboratory located within the university's centralized Materials Research Facility, which opened

its doors to the public on Nov. 28, 2019.

During the event, researchers and students in the Department of Materials Science and Engineering gave tours and demonstrations of the equipment in the lab that puts UNT at the forefront of this rapidly emerging area of technology. Additive manufacturing is capable of producing higher-strength and more energy-efficient materials while reducing the actual amount of materials needed, wear and tear on parts and use of natural resources.

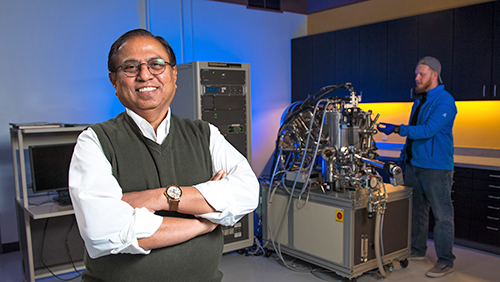

“This type of technology enables our students and faculty to dive deeper into additive manufacturing and conduct hands-on and solutions-based research,” says Yan Huang, interim dean of the College of Engineering. “They will be able to expand their research largely within many areas including aerospace and biomedical fields as well as the oil and gas industries.”

UNT is going beyond metallic 3D printing by developing methods to determine how the process affects the advanced materials. A state-of-the-art Additive Manufacturing Laboratory, AML, under the overall umbrella of the university's existing materials research facility, MRF, and sponsorship of the Offices of Vice President of Research and Innovation and the Dean of Engineering has been established with the dual purpose of research and education. UNT is the only university in the nation with this configuration, which allows for cooperation across fields to better advance the science and application of additive manufacturing.

“Many universities are involved in 3D printing, but we want to go deeper. We want to understand what is fundamentally different about the same metallic material made using 3D printing technology versus the manufacturing technologies in subtractive manufacturing,” says Rajarshi Banerjee, Regents Professor and director of the MRF. “What is the difference? Is it good, or is it bad?”

Researchers and students are using the equipment to create components such as prototypes of medical implants, which were on display at the event. Banerjee explains that the tools in the adjacent Materials Research Facility provide the capability to understand how components built by the 3D printing equipment will function in a real manufacturing system. Knowing how the process is affecting the materials is key to applying additive manufacturing in the manufacturing industry.

“The work conducted in the Additive Manufacturing Laboratory has the potential to

have broad impacts on our society,” Narendra Dahotre, interim vice president of research and innovation and Distinguished Research Professor

of materials science and engineering, said during Wednesday's event. “And UNT faculty

and student research have the opportunity to shape this emerging field - and that

is part of what makes this opening so exciting.”

“The work conducted in the Additive Manufacturing Laboratory has the potential to

have broad impacts on our society,” Narendra Dahotre, interim vice president of research and innovation and Distinguished Research Professor

of materials science and engineering, said during Wednesday's event. “And UNT faculty

and student research have the opportunity to shape this emerging field - and that

is part of what makes this opening so exciting.”

Dahotre is an internationally known expert in laser-based material processing that remains the basis of present additive manufacturing technology. In fact, Dahotre has been working on laser-based advanced materials manufacturing for the past three decades, even before the additive manufacturing term was coined. Dahotre, in collaboration with three College of Engineering professors Rajarshi Banerjee, Rajiv Mishra, and Andrey Voevodin, conceived the concept of the AML and led the efforts to bring it into existence.

The Additive Manufacturing Laboratory is a comprehensive and centralized facility, bringing together both types of additive manufacturing - laser powder bed fusion (LENS 750), also referred to as selective laser melting, and laser-based directed energy deposition (Aconity MIDI) - along with several pre- and post-process equipment for fundamental and applied research on additive manufacturing. The lab will foster UNT's interdisciplinary research in the area of advanced manufacturing.

“It's facilities like these this that help put us on the map,” UNT President Neal Smatresk said at the event. “Here in Texas, the industry is a little behind, and this laboratory is key to helping us advance this area now. Investing in our infrastructure is key as we work toward building our reputation as a nationally prominent research university.”

UNT is requesting state funding for UNT's Center for Agile and Adaptive Additive Manufacturing to create a Texas-based prototype center that could globally transform the future of manufacturing. The Additive Manufacturing Laboratory will be one of the assets to support the center. Research conducted at the lab will lead to smart materials and environmentally-friendly technologies while helping develop a trained workforce of engineers.

By Jim Rogers, UNT News, Dec. 18, 2019

Image: Yan Huang, interim dean of the College of Engineering, left, Narendra Dahotre, CAAAM founder, and Neal Smatresk, UNT president.