Core Facilities & Capabilities

Laser Powder Bed Fusion

Aconity MIDI SLM System

The Aconity MIDI SLM System is a cutting-edge high-quality 3D laser metal-printer for research into advanced

fabrication of material structures, innovative metal alloys, metal-and-ceramic composites

and other materials. This machine features a1kW laser, interchangeable build diameters

from 50 to 170mm, a high-temperature build platform controllable up to 1200C, and

a high-speed camera system and two pyrometers for in-situ process monitoring.

Trumpf TruPrint 1000

With a cylindrical build volume of 100 mm in diameter and 100 mm in height, the TruPrint 1000 can be used for the generative production of small industrial single parts and series

in almost any geometric shape. Even relatively complex shapes can be quickly and easily

converted from the CAD design to a top-quality 3D metallic component in a wide variety

of common alloys, aerospace alloys, and refractory alloys. It also comes with in-situ

monitoring through a camera and simple feature recognition.

Trumpf TruPrint 2000

With its small 55-μm laser beam diameter, the TruPrint 2000 provides a high-quality printing result that impresses with its surface quality and

level of detail. It offers a cylindrical build volume of 200 mm in diameter and 200

mm in height. The laser has been upgraded to 500W to accommodate processing of refractory

materials. It also comes with a heated stage controllable up to 200C. The TruPrint

2000 has a powder preparation station for fast and simple pre/post-processing powders,

and is completely enclosed so the user does not come into contact with the powder.

Directed Energy Deposition

Optomec LENS-750

The Optomec LENS-750 Laser Engineered Net Shaping System is a highly flexible 3D printer that uses metal

for manufacturing, processing, and advanced research on alloy development. Featuring

four independent powder hoppers, this machine can be used to make compositionally

and functionally graded materials.

Optomec LENS CS-250

The LENS CS-250 System is the latest model to come out of Optomec Inc. Featuring four powder hoppers,

this machine can be used to make compositionally and functionally graded materials.

This machine also comes with a 5-axis system to enable complex shapes and repairs

on existing geometries. A 1KW nLight laser system can be used to print highly reflective

materials like copper and its alloys, and an onboard lens changing system allows the

user to change the laser spot size between materials, or within a single setup.

Hybrid Manufacturing AMBIT™

The Hybrid Manufacturing AMBIT™ combines both the additive and subtractive part of manufacturing in one system. Featuring

the latest patented and award-winning AMBIT™ laser-based directed energy deposition

heads, we can deposit metal using interchangeable 1mm and 3mm beam widths. Additional

types of laser processing are supported by the Series 7 system for drilling, ablating

and finishing metal.

Solid State Processing

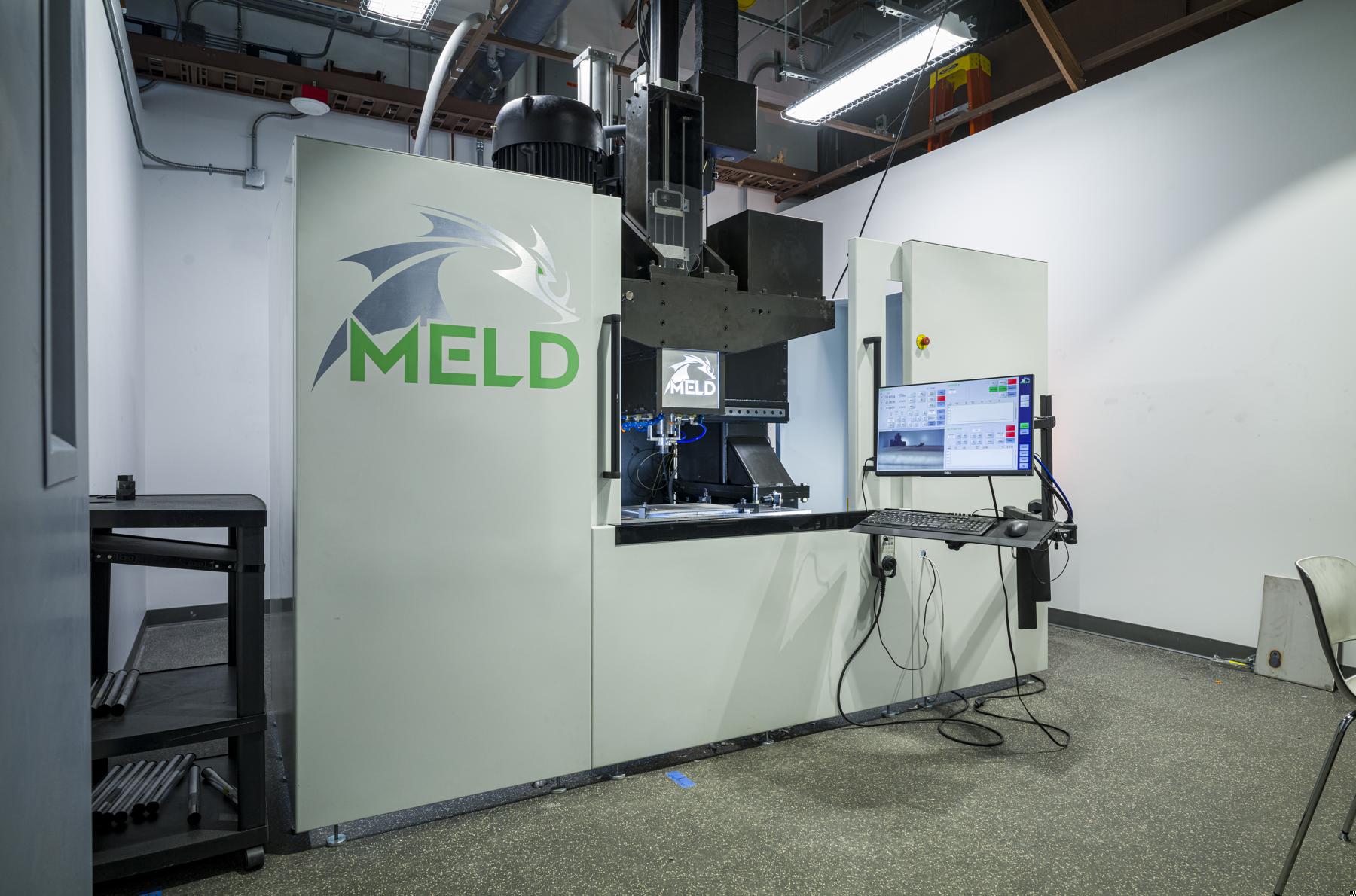

MELD B8: Solid-State Processing

MELD B8: Solid-State Processing is a solid-state process, meaning the material does not reach the melting temperature

during the process. It offers a wide range of capabilities, including additive friction

stir deposition (AFSD), coating applications, component repair, metal joining, and

custom metal alloy and metal matrix composite billet and part fabrication. MELD is

a single-step process that does not require time-consuming, follow-on processes such

as hot isostatic pressing (HIP) or sintering to improve the quality of the deposited

material.

Binder Jetting

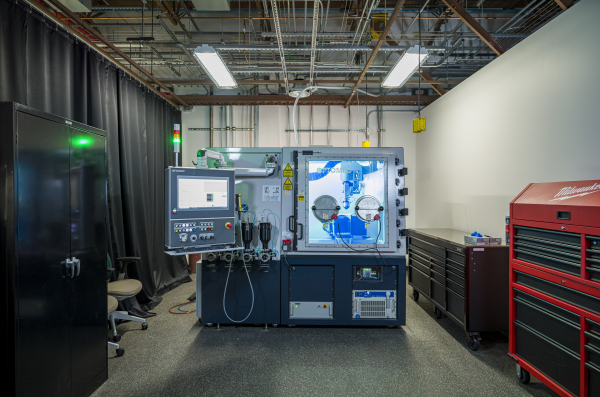

ExOne Innovent+

A multipurpose additive tool with increased dust control and the most advanced powder

dispensing on the market. Innovent+™ is designed to reliably produce functional parts

in a variety of materials. It is easy to use and features state-of-the-art recoating

technology, allowing for the widest range of materials to be printed while producing

the most consistent and uniform print bed. This machine can process a wide range of

powders, including metals, ceramics, composites and other powder materials.

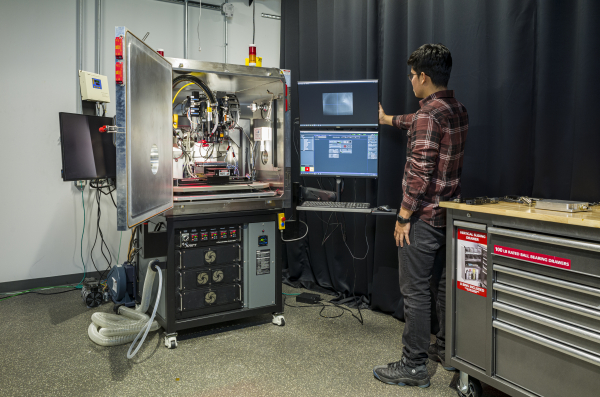

Precision Microdispensing System

nScrypt 3Dn

The 3Dn Series is a gantry-based, high-precision motion platform running nScrypt Machine

Tool Software for exceptional control. For example, the user can configure the system

with multiple Micro-Dispensing tool heads (gizmos) or multiple heads of different

functionality, such as material extrusion, micro-milling, or pick and place. Other

options include laser sintering, heating, UV curing, laser mapping, and onboard imaging,

and has been fitted with atmosphere control and monitoring equipment as well as in-situ

monitoring equipment. Regardless of configuration, the platform builds fine features

at high speeds.

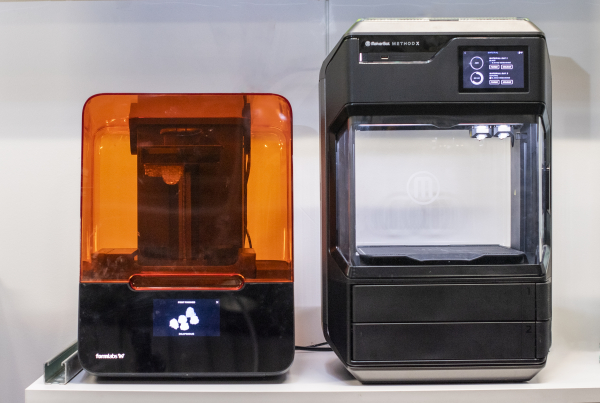

Fused Deposition Modeling and Stereolithography

ZORTRAX M200+, MAKERBOT METHOD X, FORMLABS FORM 3+, MARKFORGED MARK TWO

Our small-sized printers are used for both classroom and polymer-based research. Materials

vary from plastics such as ABS and PC-ISO, fiber-reinforced polymers, and various

resins, with feature sizes as small as 25 microns and build volumes as large as 5600cc.

Powder Processing

TEKNA TekSphero-15: Spheroidization System TekSphero-15

The TEKNA TekSphero-15: Spheroidization System TekSphero-15 is a plasma treatment system uniquely designed to manufacture and process metal and

ceramic powder, which enables the design and prototyping of new materials for additive

manufacturing. The unique design of the inductively coupled plasma eliminates any

potential contamination from potential electrode materials seen in other plasma equipment.

This unit is equipped with a spheroidization reactor and a nanoreactor to produce

a powder with a particle-sized distribution from nano to micro scales. The lab-scale

design of this unit allows for rapid turnarounds of experimental and computational

materials design.