Summer Program Training and Outreach

List of Instructors and Online Program Schedule

July 25, 9 a.m.–noon

Module 1: Why 3D printing — the excitement of processes and materials!

Dr. Hector Siller

Dr. Sameehan Joshi

July 26, 9 a.m.–noon

Module 2: Sustainability and energy in materials science: the importance of additive manufacturing

Dr. Srinivasan Srivilliputhur

July 27, 9 a.m.–noon

Module 3: Supply Chain Management and Logistics for AM

Dr. Suman Niranjan

Dr. Arunachalam Narayanan

Himali Patil

July 28, 9 a.m–noon

Module 4: Data Science and Data Analytics

Dr. Song Fu

July 28, 1–4 p.m.

Module 5: Cybersecurity issues in 3D printing

Dr. Lida Haghnegahdar

July 29, 9 a.m.–noon

Module 6: Toward an in-depth understanding of 3D printing — Process Diagnostics

Dr Yuqi Jin

Brian Squires

In-Lab Activities and Exercises

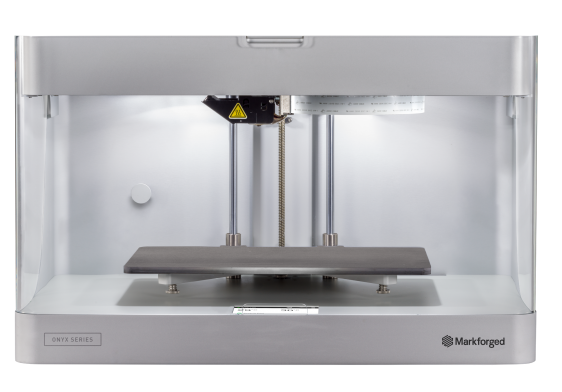

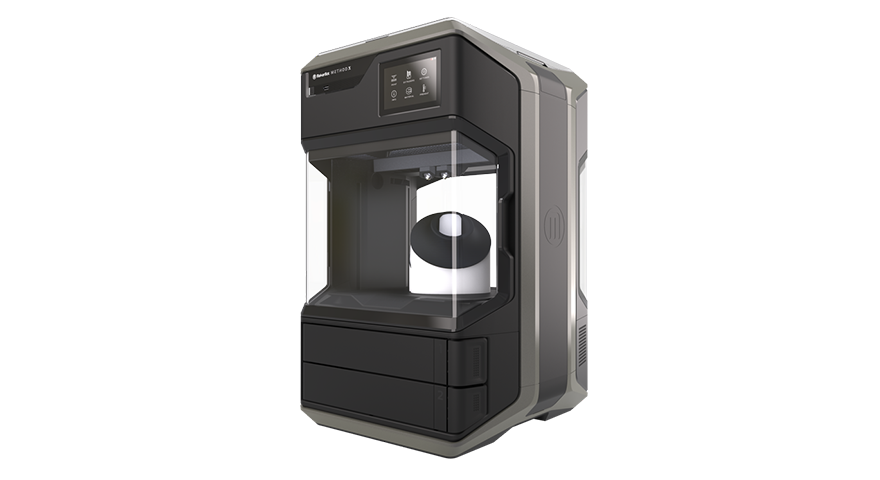

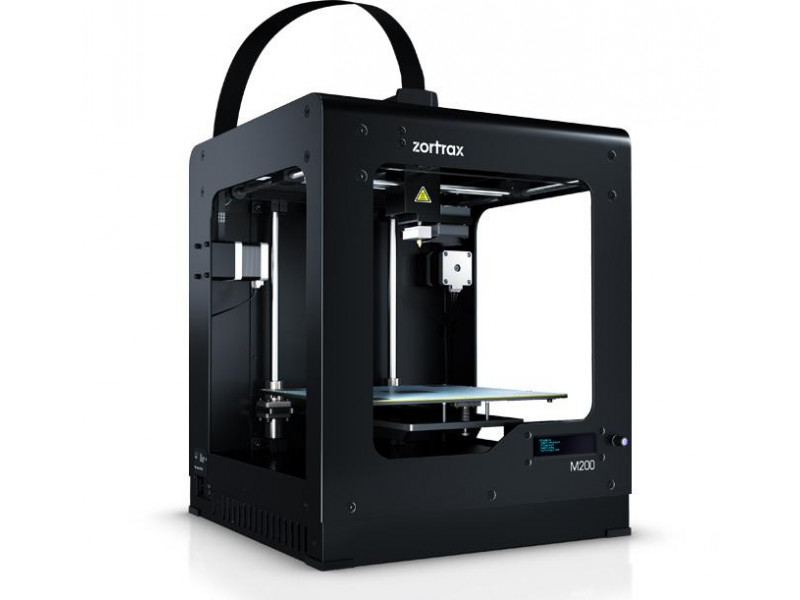

Laboratory 1: 3D printing of polymers/plastics

Learning Objective: The student will gain experience in the use of additive manufacturing equipment based on filament fabrication (Fused Deposition Modeling), vat photopolymerization,and other polymer 3D printing techniques.

Deliverables: After learning how to pre-process, fabricate and post-process 3D-printed parts, the students will present a brief report and a fabricated part.

Laboratory 2: 3D printing of metals

Learning Objective: The student will develop practical knowledge on the fabrication of metallic parts by different additive manufacturing techniques, namely laser powder bed fusion (L-PBF), direct energy deposition, DED, and hybrid manufacturing.

Deliverables: The students will present a brief report about their findings and to discuss the impact of process parameters in the quality of the fabricated parts.

View on YouTube: Trumpf TruPrint 1000: Laser Powder Bed Fusion

View on YouTube: Hybrid Manufacturing Technologies Ambit: Directed Energy Deposition

Laboratory 3: 3D printing of ceramics and other materials

Learning Objectives: The students will perform different tasks for the fabrication of composite parts made by binder jetting and with functional materials.

Deliverables: The students will present a brief report about the characteristics of the fabricated parts and will discuss the capabilities of binder jet technology to fabricate functional materials.

View on YouTube: Exone Innovent+: Metal Binder Jetting

Laboratory 4: Open-lab session about additive manufacturing

Learning Objectives: The students will develop extra knowledge on a topic of their preference and will work in pending homework assignments with the Edupack software for Materials Science.

Deliverables: Edupack exercises and discussion about the importance of additive manufacturing in the industry.